Machine Menu

"The GoTorch is the handiest machine in our shop. We end up using it every day to make replacement

parts for our heavy equipment. Sometimes we even take it on the job."

Don Ireland

Excavation

Customizable

This frame is used to cut small pieces of material. The machine and a piece of standard grating fit into the frame and can be easily lifted out.

The GoTorch® system is perfect for those wanting to customize or build their own CNC machines. You get a fully-functioning system with minimal initial

investment.

This gives you the freedom and convenience to start making parts immediately while taking the time you need to decide if and how you

want to expand the size or capabilities of the machine.

You will find that making the ultimate machine you want is easy because the most critical and advantageous components are already designed and

provided for you out of the box - the servo motors, electronics, and controlling software.

Expandable

The GoTorch machine can be conveniently expanded in various ways. You can build your own simple frame to support the material.

The GoTorch is only sold as a 2ft by 2ft table. However, you can expand the machine to many standard sizes. Our stock components can be used to

build any size of machine that is 2, 4 or 5 feet wide by 2, 4, 5, 8 or 10 feet long. The cost of these parts (in addition to any custom frame) ranges from

about $400 to $1600, depending on the size you want.

You can also build or modify components yourself to make the GoTorch machine virtually any other size you want. An additional software add-on is required

for changing the machine size.

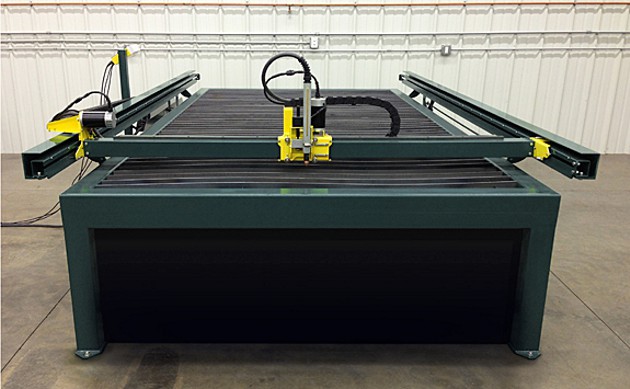

This heavy-duty 6ft by 12ft machine was made by installing modified stock components onto a fully custom frame. It even has a lever that lowers the rails below the sides for rapidly loading and unloading with a forklift.

Adaptable

The GoTorch machine can be adapted for a variety of applications when you use other tools and materials. For example, you can cut pipe, or you can cut wood or plastic with a router and optionally carve 3D images. There is no end to the possibilities that GoTorch gives you the freedom to achieve!

This machine was expanded to cut a 2ft by 4ft area by installing longer stock rails. A router is used in place of the plasma torch to cut corrugated sheet

metal for custom-fit roofing.

This machine was expanded to cut a 2ft by 4ft area by installing longer stock rails. A router is used in place of the plasma torch to cut corrugated sheet

metal for custom-fit roofing.

This pipe cutting machine was made by installing the optional pipe cutting attachment onto a custom frame. It cuts letters, designs, holes, or notches in pipe up to 13½ inches in diameter.

To keep costs low, optional products are purchased directly on the Owner's Community after you buy your machine. They include art discs, more advanced software options, automatic height control, engraving and routing options, 3D capability, additional seat licenses, and parts for expanding the size of the machine, cutting pipe and maintenance.